How Can We Help?

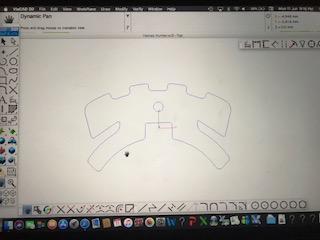

At Profile Extrusions we offer onsite CAD design and a full tool room facility incorporating EDM wire cutting, allowing us to assist you in every step of production from concept to world-ready finished product.

We utilise five extrusion lines covering most grades of flexible and rigid plastics, including Co-Extrusion capability. Commonly processed materials include: uPVC, fPVC, ABS, AES, HIPS, TPR, TPE, TPU, PP and all Polythene grades.

We offer a complete manufacturing service from bulk supply to finished product cut to required length. We can also assist with packaging and labelling for direct supply to point-of-sale.

Product identification by online printing is also available.

We offer recycling capability to our customers for materials we have processed and incorporate recycled materials and in-house recycling initiatives where possible.

Transportation is available nationwide for all goods manufactured and worldwide on request.